Waste analysis by WESSLING – we are partners with the waste management industry

At WESSLING, we regard waste as a valuable material – according to the principle: prevention before recycling before disposal. At WESSELING, waste analysis means that we analyse the composition of residues so that they can then be specifically reused in agriculture,in industry or as fuel.

The European Waste Framework Directive (2008/98/EC) defines how companies must handle waste: on principle, residues should always be avoided when possible. If this is not realistic, efforts must be made to attempt recycling prior to disposal. WESSLING supports you in your recycling process: in our specialised and accredited laboratories, we analyse waste and residues of various kinds – including compost, sewage sludges or fuels.

Of course, we also provide you with comprehensive advice on how best to avoid and reduce waste within your processes – because we regard waste analysis as a holistic process. Our experts ensure that you incur the lowest possible costs due to valuable material recycling, but also through analysing and optimising processes.

Waste analysis – our services in detail

Waste analysis – our services in detail

Compost and fermentation products

Analysis of compost and fermentation products

The use of quality-assured compost as a multi-nutrient fertiliser is attractive in various regards. Fertiliser analyses that are recognised by the German Federal Compost Quality Association (BGK - Bundesgemeinschaft Kompost e.V) must be carried out regularly as part of the RAL quality assurances. The WESSLING laboratory specialists have many years of experience and know-how in analysing compost. Both our sampling and our ultra-modern test laboratories are recognised by the BGK. Here, our experts analyse your samples for physical, chemical and biological parameters, nutrient contents, hygiene parameters and heavy metals.

Our range of services

- Sampling as specified and recognised by the German Federal Compost Quality Association (BGK)

- Laboratory analysis of all parameters according to the specifications of the German Federal Compost Quality Association or fermentation substrate for finished compost, fresh compost, mulch compost, substrate compost, solid and liquid fermentation products

- Analysis of typical, special compost parameters such as microbiological hygiene parameters (aerobic bacterial count, faecal coliform bacteria, enterococci)

- Special analysis for the parameters of perfluorinated tensides (PFT, e.g. PFOA, PFOS), plasticisers such as phthalates, calorific value, etc.

We regularly and successfully take part in ring trials.

Waste analysis – our services in detail

Substitute and secondary fuels

Analysis of substitute and secondary fuels

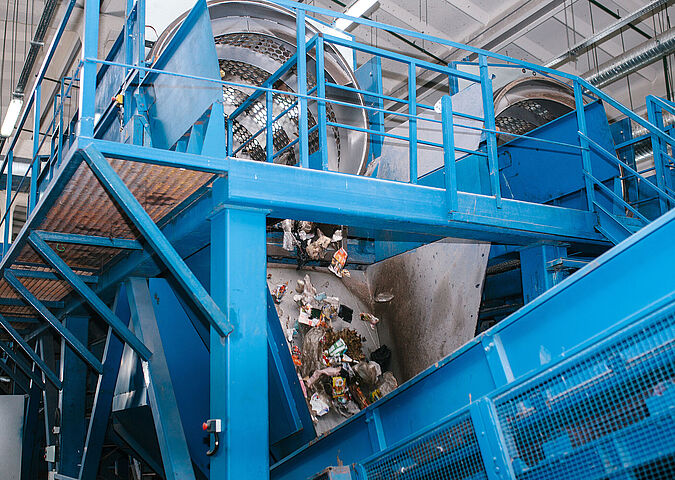

The principle of the European Waste Framework Directive is "prevention before recycling before disposal". This principle has been implemented in national legislation. A range of sorting and waste processing plants, in which diverse fuels are manufactured from waste, has been established as a result of this. These include SBS (substitute fuel from municipal waste), EBS (substitute fuel from hazardous waste), BRAM (substitute fuel from waste) and BPG (fuel from production-specific commercial waste).

Our range of services

All services from receiving inspection and production up to and including the emission declaration are available on request from one source at WESSLING . This offers you an objective assessment of your fuels as well as assistance in the event of complex questions concerning your products.

- Sampling of waste and fuels

- Analysis of numerous matrices with optimised sample preparation and analysis methods adapted to the sample matrix

Our services for your industry

WESSLING provides individual service packages that are tailored to the needs of your company.

Your contact for the topic of waste analysis

- Charly Wang

- +86 21 337 253 67

- charly.wang@wessling.cn

„Waste is not simply waste: our laboratory analysis provides findings showing recycling possibilities concealed in your waste.“

Precise analysis services and smooth sample logistics for waste

The quality of sampling, sample preparation and laboratory analysis is fundamental for dependable results. We have decades of experience in the field of waste and fuel analysis.

Our range of services:

- Analysis of waste, sewage sludges and other residues

- Analysis of waste from mechanical-biological waste treatment plants

- Analysis of compost as per the German Federal Compost Quality Association (BGK)

- Analysis of residues from agriculture or biogas plants

- Analysis of substitute and secondary fuels, used oil or used wood

- Declaration analysis of mineral waste